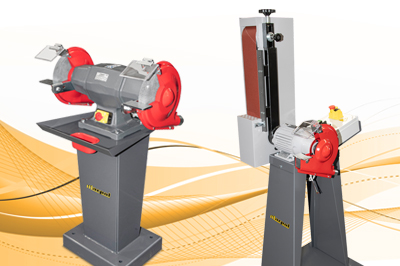

Grinder and sander. The subtle but important difference

Insiders, professionals, know very well the difference between a grinder and a sander. Let us clarify.

Grinding, i.e. cleaning, polishing, smoothing, removing unnecessary parts, improving geometries or bevelling. Making a workpiece translucent, in our case metal, but also wood, plastic, marble or ceramic, by removing a large amount of material with the use of abrasive belts or discs.

Sanding, i.e. accurately smoothing a surface, levelling it out, giving the workpiece excellent precision characteristics, perhaps eliminating small roughness defects or improving couplings by removing small amounts of material in the order of tenths or hundredths of a centimetre using abrasive belts or discs.

For professionals, grinding mainly means cutting, removing rust and polishing a surface even if not extremely precisely and with a normal degree of finish. The result varies depending on the type of belt or disc used. For a final result with a high degree of surface finish and precision, the sanding process is certainly more optimal.

In both cases the experience and the hand of the operator are crucial for the final result and for keeping subsequent correction costs down. The speed of the machine, the type of belt or disc used, the manual pressure exerted, the contact surface involved, all contribute to heating or not heating the material and influence the final result.

The advantage of working with grinders or sanders is that the workpiece does not have to be clamped and can be manoeuvred, turned and pressed according to requirements and sensitivity.

Due to the fact that both the mechanical actions of grinding and sanding are abrasive processes, particles of material are generated which can be contained in our machines by the extraction systems we have built into the machines.

Write to info@marpolfr.com

for the contact details of retailers.